3D Printable Threads

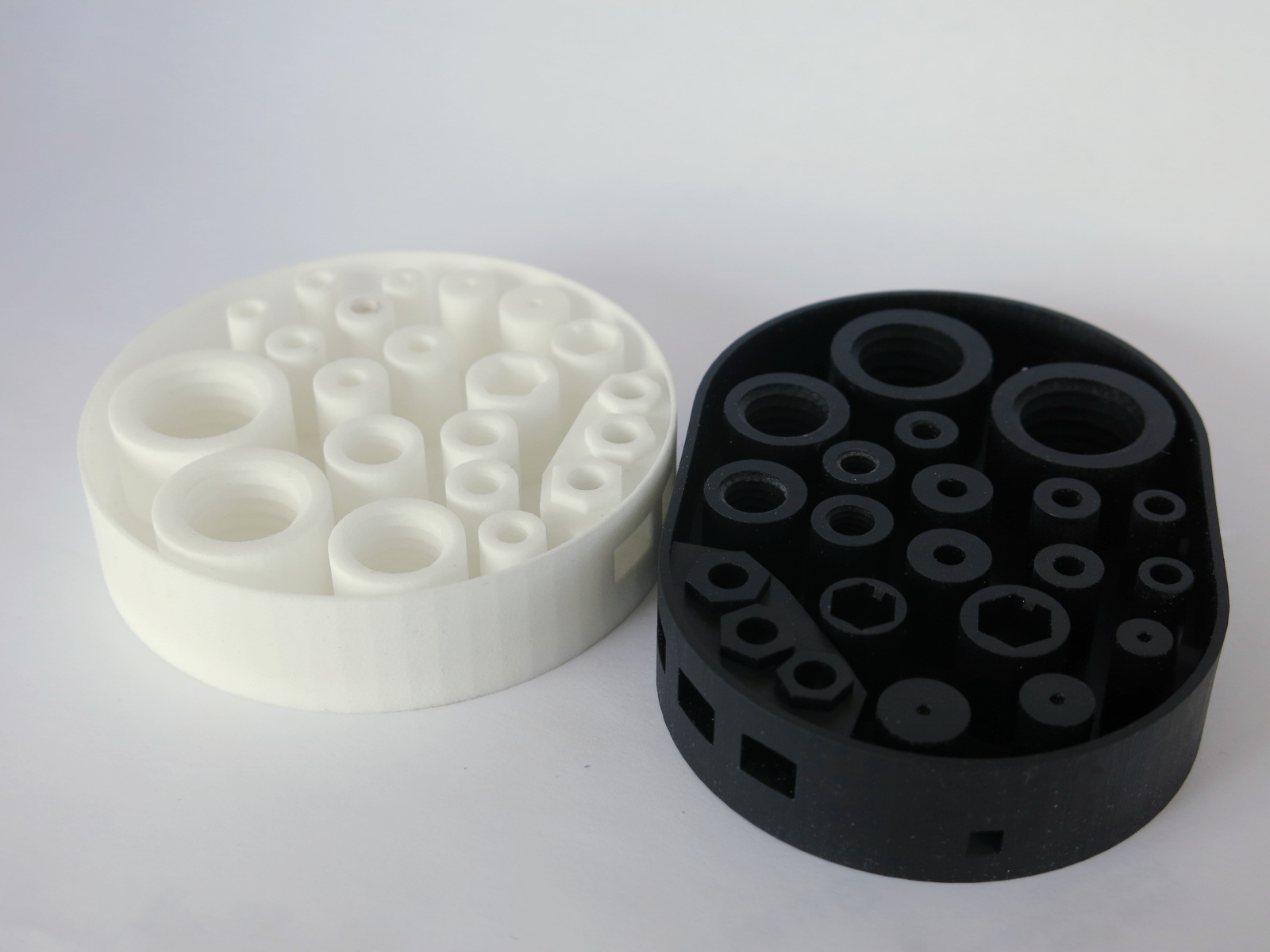

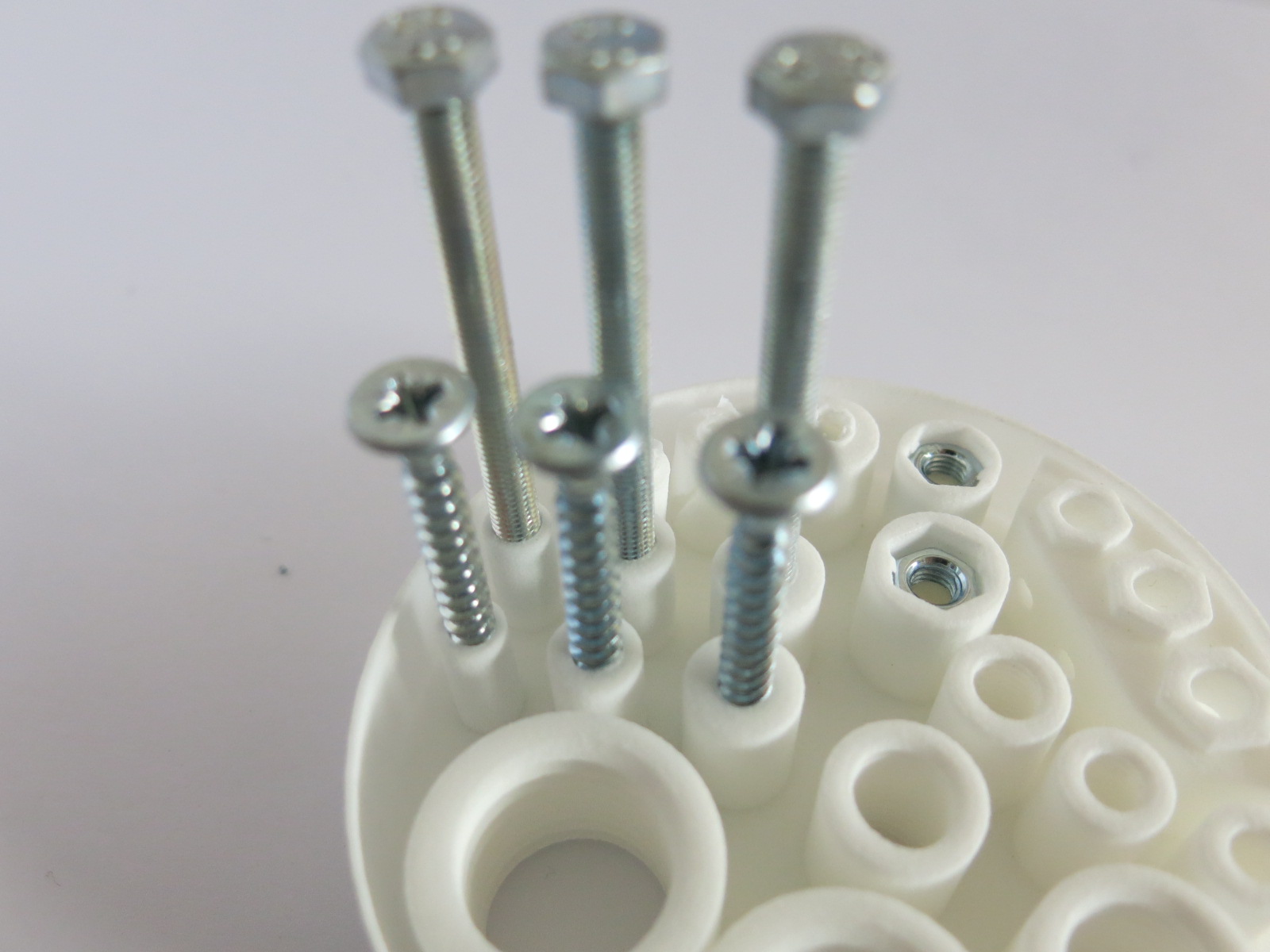

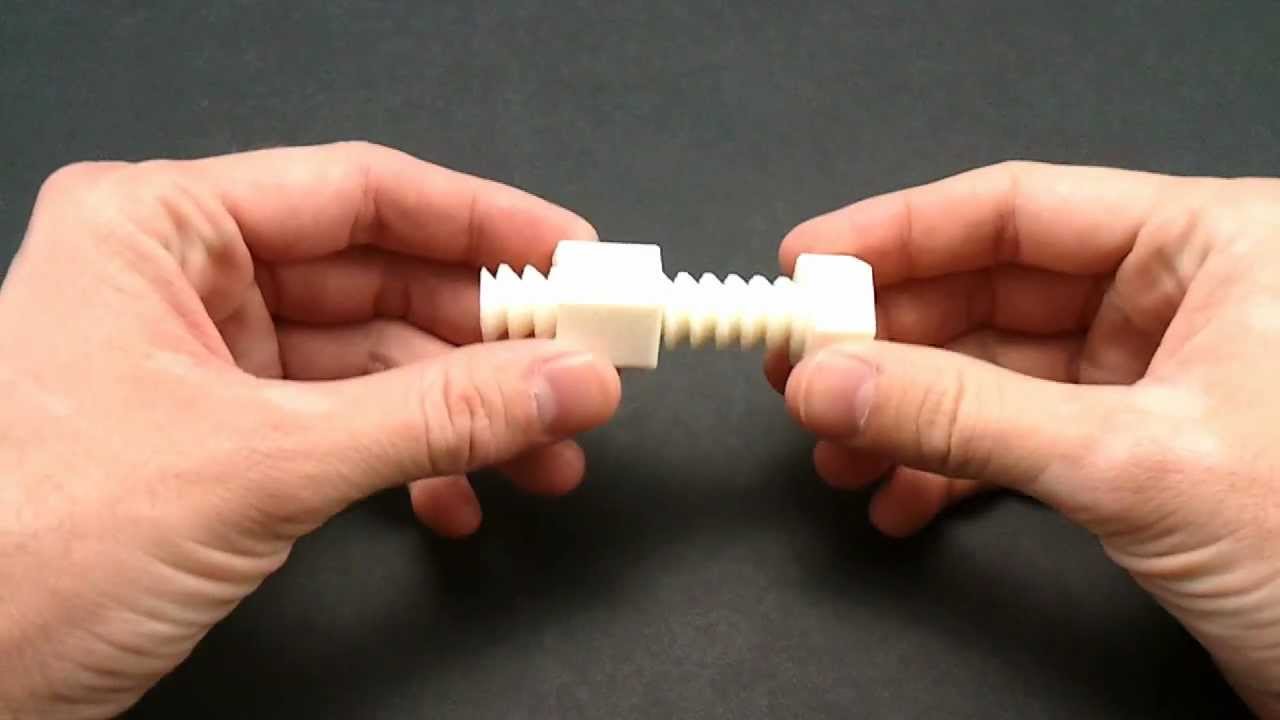

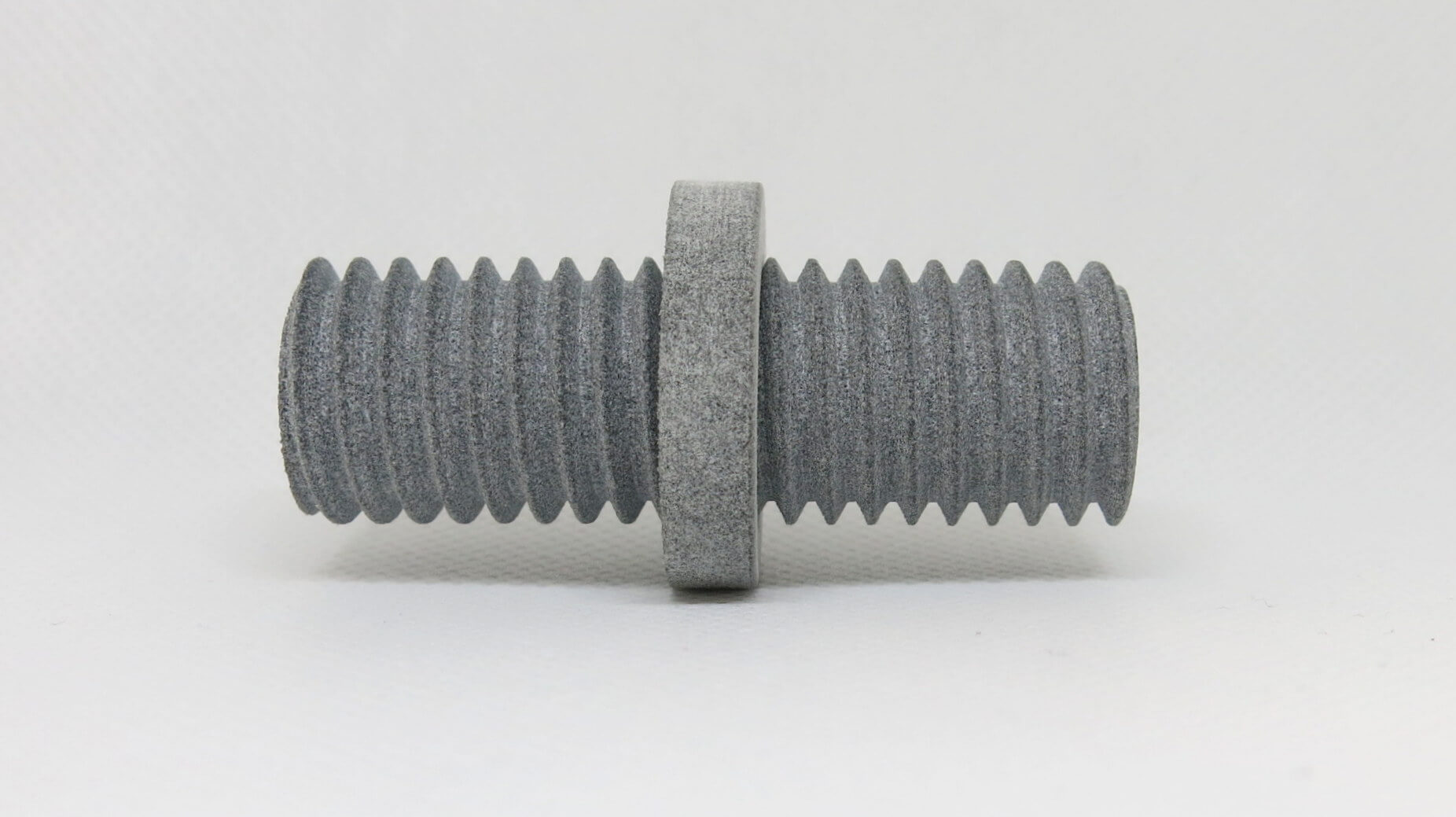

3D Printable Threads - 3d printers can create highly accurate and durable physical parts with almost unlimited complexity and detail. Learn the best methods for adding threads to 3d printed parts, from tapped holes to metal inserts, for stronger and more durable connections. This makes them attractive to designers, building functional. Triangular thread forms can be classified based on the triangle's shape and the pitch of the helical curve, categorized into metric threads and inch threads. This guide will walk you through the essentials, from designing threads using cad. This method involves designing the threads into the part using cad software and then printing the. Learn about the various ways to 3d print threads, screws, and threaded inserts to combine multiple 3d printed parts for a robust mechanical fastening. Utilize 3d printed threads and screws to enhance the functionality and customization of your designs. As a beginner, diving into the world of 3d printed threads can seem daunting, but fear not. Learn how to design threads in 3d printed parts using solidworks, autodesk fusion 360, inventor, creo, sketchup, onshape, and tinkercad. It depends on the thread. Unfortunately, not all printing proesses can reliable produce threads,. Learn how to design threads in 3d printed parts using solidworks, autodesk fusion 360, inventor, creo, sketchup, onshape, and tinkercad. Learn the best methods for adding threads to 3d printed parts, from tapped holes to metal inserts, for stronger and more durable connections. An example would be the thread tool and coil tool in fusion. Learn about the various ways to 3d print threads, screws, and threaded inserts to combine multiple 3d printed parts for a robust mechanical fastening. This method involves designing the threads into the part using cad software and then printing the. Triangular thread forms can be classified based on the triangle's shape and the pitch of the helical curve, categorized into metric threads and inch threads. In this video, i’ll give you an overview of the options you have, show you the easiest ways to use them in your own designs, and then rate each one based on ease of use,. Utilize 3d printed threads and screws to enhance the functionality and customization of your designs. Learn about the various ways to 3d print threads, screws, and threaded inserts to combine multiple 3d printed parts for a robust mechanical fastening. Triangular thread forms can be classified based on the triangle's shape and the pitch of the helical curve, categorized into metric threads and inch threads. Utilize 3d printed threads and screws to enhance the functionality and. 3d printers can create highly accurate and durable physical parts with almost unlimited complexity and detail. In this video, i’ll give you an overview of the options you have, show you the easiest ways to use them in your own designs, and then rate each one based on ease of use,. An example would be the thread tool and coil. Utilize 3d printed threads and screws to enhance the functionality and customization of your designs. As a beginner, diving into the world of 3d printed threads can seem daunting, but fear not. An example would be the thread tool and coil tool in fusion. The applications and benefits of 3d printed threads and screws. This method involves designing the threads. This makes them attractive to designers, building functional. Learn about the various ways to 3d print threads, screws, and threaded inserts to combine multiple 3d printed parts for a robust mechanical fastening. Unfortunately, not all printing proesses can reliable produce threads,. 3d printers can create highly accurate and durable physical parts with almost unlimited complexity and detail. It depends on. This makes them attractive to designers, building functional. 3d printers can create highly accurate and durable physical parts with almost unlimited complexity and detail. Learn the best methods for adding threads to 3d printed parts, from tapped holes to metal inserts, for stronger and more durable connections. Triangular thread forms can be classified based on the triangle's shape and the. The applications and benefits of 3d printed threads and screws. This makes them attractive to designers, building functional. An example would be the thread tool and coil tool in fusion. As a beginner, diving into the world of 3d printed threads can seem daunting, but fear not. In this video, i’ll give you an overview of the options you have,. One of the most effective ways is to print the threads directly onto the part. It depends on the thread. Utilize 3d printed threads and screws to enhance the functionality and customization of your designs. This guide will walk you through the essentials, from designing threads using cad. However, with advancements in additive manufacturing technology, creating threads is now possible. One of the most effective ways is to print the threads directly onto the part. This guide will walk you through the essentials, from designing threads using cad. In this video, i’ll give you an overview of the options you have, show you the easiest ways to use them in your own designs, and then rate each one based on. Triangular thread forms can be classified based on the triangle's shape and the pitch of the helical curve, categorized into metric threads and inch threads. The applications and benefits of 3d printed threads and screws. As a beginner, diving into the world of 3d printed threads can seem daunting, but fear not. The vhs mold cleaner is a fairly simple. In this video, i’ll give you an overview of the options you have, show you the easiest ways to use them in your own designs, and then rate each one based on ease of use,. As a beginner, diving into the world of 3d printed threads can seem daunting, but fear not. Triangular thread forms can be classified based on. This method involves designing the threads into the part using cad software and then printing the. Triangular thread forms can be classified based on the triangle's shape and the pitch of the helical curve, categorized into metric threads and inch threads. The vhs mold cleaner is a fairly simple machine. This guide will walk you through the essentials, from designing threads using cad. Learn the best methods for adding threads to 3d printed parts, from tapped holes to metal inserts, for stronger and more durable connections. It depends on the thread. Utilize 3d printed threads and screws to enhance the functionality and customization of your designs. Learn how to design threads in 3d printed parts using solidworks, autodesk fusion 360, inventor, creo, sketchup, onshape, and tinkercad. However, with advancements in additive manufacturing technology, creating threads is now possible with 3d printing. One of the most effective ways is to print the threads directly onto the part. Learn about the various ways to 3d print threads, screws, and threaded inserts to combine multiple 3d printed parts for a robust mechanical fastening. In this video, i’ll give you an overview of the options you have, show you the easiest ways to use them in your own designs, and then rate each one based on ease of use,. An example would be the thread tool and coil tool in fusion. Unfortunately, not all printing proesses can reliable produce threads,.MakeEveryDay 36 How To Make 3D Printed Threads LIKE A BOSS! YouTube

3D Printing Threads & Screws Simple Guide All3DP

Designing 3D Printed Screw Threads

Fusion 360 tutorial 3D printable Thread 3D design using Autodesk

Designing 3D Printed Screw Threads

3D Printing Threads 3D Printed Thread Freecad Thread Tutorial

How To Design 3D Printable Threads in Solidworks NUT YouTube

3DPrinted Screw Threads YouTube

A Beginner's Guide to 3D Printing Threads RapidDirect

Easy Guide Designing and 3D Printing Threads

The Applications And Benefits Of 3D Printed Threads And Screws.

3D Printers Can Create Highly Accurate And Durable Physical Parts With Almost Unlimited Complexity And Detail.

As A Beginner, Diving Into The World Of 3D Printed Threads Can Seem Daunting, But Fear Not.

This Makes Them Attractive To Designers, Building Functional.

Related Post: